Clearflow Australia generally recommends pigging as their preferred pipeline treatment. It is the safest, fastest and most cost-effective method of cleaning and refurbishing pipelines of any size.

Pigging produces a complete clean, longer-term results and extends the time-frames for repeat treatment.

- it produces the best result in terms of removing built-up debris, bio-films, sediments and scale adhered to the internal pipeline surface;

- independent lab testing shows that pipeline pigging residue contains a much higher level of suspended solids and other impurities in comparison with air scouring the same pipeline;

- it is solution specific for cleaning and refurbishing older cast iron reticulation mains so they can remain in use; and

- it is ideal for longer distance pipelines.

Pigs

Pigs are a determining factor in pipeline cleaning success. A pig is a device that is larger than the internal bore of the pipe. It is inserted into and forced through a pipeline using hydraulic or pneumatic pressure. The force created completely dislodges all built-up contaminants, scale and debris inside the pipe and pushes it to a pre-determined collection or release point.

Pigs need to be the correct size and shape, and need to be made out of the most suitable compound for the circumstances of the pigging exercise. Clearflow Australia is not buyer or distributor of pigs. We assess each pipeline and source the most appropriate pig for the task. Where necessary, we design and commission pigs that are purpose built for each project to ensure complete removal of bio-films and other contaminants.

Launchers and receivers

Pigs are introduced into the pipeline is through a launcher and they exit the pipeline through a receiver – collectively called pig traps.

In older pipelines launchers and receivers were not part of the original construction, making cleaning and maintenance difficult. Clearflow bypasses this problem by installing temporary launchers and receivers, which are removed on completion of a job and the original pipeline is restored.

Most clients with older pipeline infrastructure take the practical, long term and cost-effective option of installing permanent launchers and receivers, which become part of the pipeline infrastructure. The one-off cost of installation reduces the cost of all future pigging services.

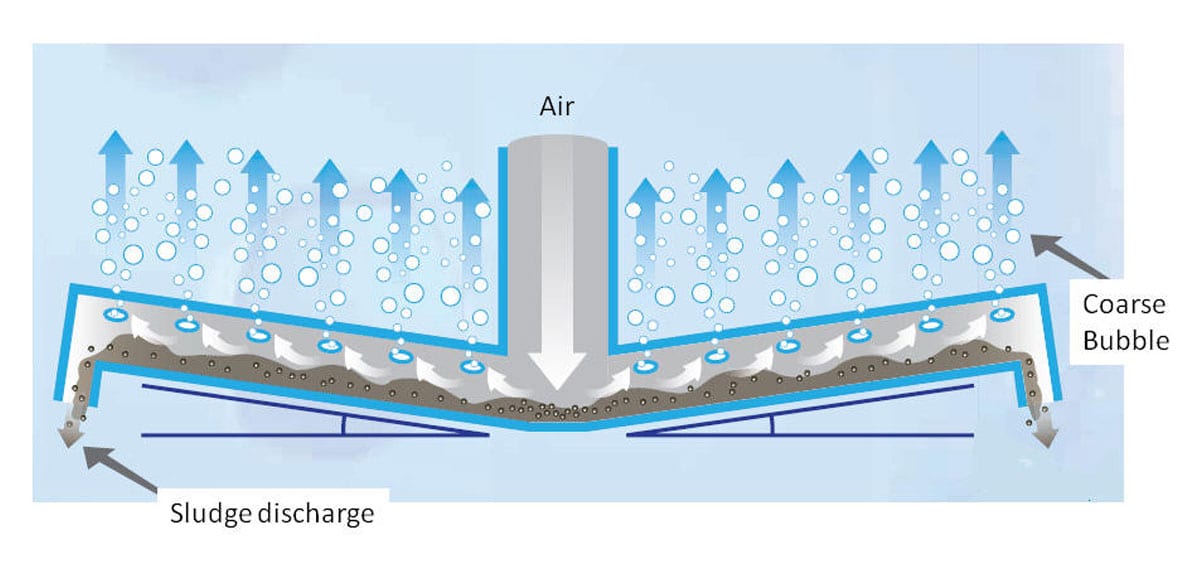

Air Scouring

Air scouring is more economical than pigging and produces far better results than flushing. It is the most environmentally responsible of all pipeline cleaning processes because it uses the least amount of water, no chemicals and as there are is no contamination of the discharge waste, the water can be dispersed on-site. Air scouring is our most purchased service.

Purified compressed air and water are injected into a pipeline at the same time and the turbulence created removes silt, scale, bio-films sediments, and contaminants. The residue and waste are expelled through a controlled outlet at a predetermined exit point.

Air scouring is ideal for cleaning difficult to reach areas such as tight bends. One of air scouring’s important characteristics is that it prevents damage to the internal bore of all pipelines, including cement-lined pipes.

It is the most environmentally responsible of all pipeline cleaning processes because it uses the least amount of water, no chemicals and as there are is no contamination of the discharge waste, the water can be dispersed on-site.

If you would like a comparative analysis of pipeline pigging and air scouring options please complete the form below.